As part of GreenBlue Urban’s commitment to continually improve products and solutions, we recently commissioned Lucideon, an independent material testing and analysis laboratory, to investigate the structural properties of the RootSpace Airform® soil cell system.

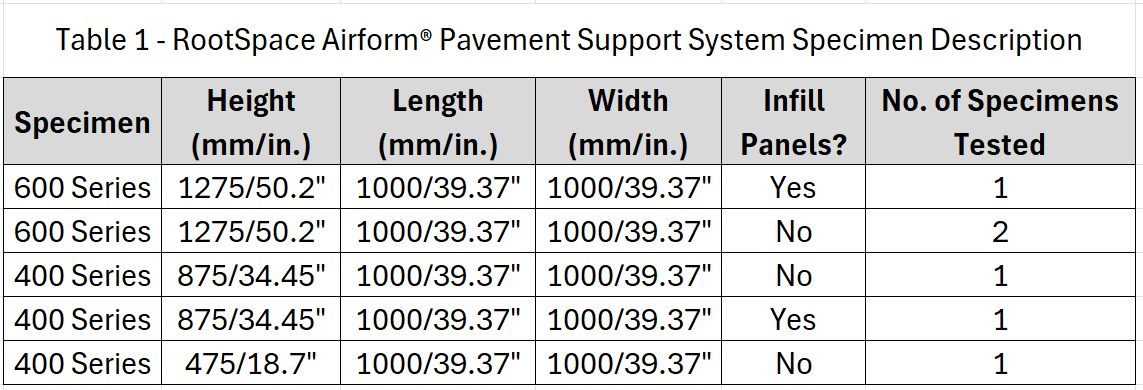

For testing, Lucideon was supplied with RootSpace Airform® soil cell components assembled into various module sizes, as outlined in Table 1. The samples, constructed by Lucideon’s technicians, included different series (600 and 400) with varying heights, lengths, and widths. Some tests also considered infill panels to assess their impact on structural performance. Each sample underwent Uniformly Distributed Load (UDL) testing to determine its compression strength and deflection characteristics.

These tests, carried out to BS EN 17150 standards, aimed to assess the structural integrity and load-bearing capacity of RootSpace Airform® under different configurations and infill conditions. The results provide valuable insights into the performance of RootSpace Airform® in our urban infrastructure, including pavement support and underground conveyance and storage systems.

Test Program and Methodology:

The testing program involved conditioning all samples in the air at the test temperature for at least 24 hours. Subsequently, each sample was subjected to a constant rate of compression using a servo-assisted hydraulic loading machine, with load and deflection measurements monitored throughout testing.

A pre-load was applied for 5 minutes to allow the specimen to set before continuous loading until failure occurred. The compressive load was applied at a constant rate of .5kN/m2/s, following Method A in BS EN 17150:2019 standards.

Results and Analysis:

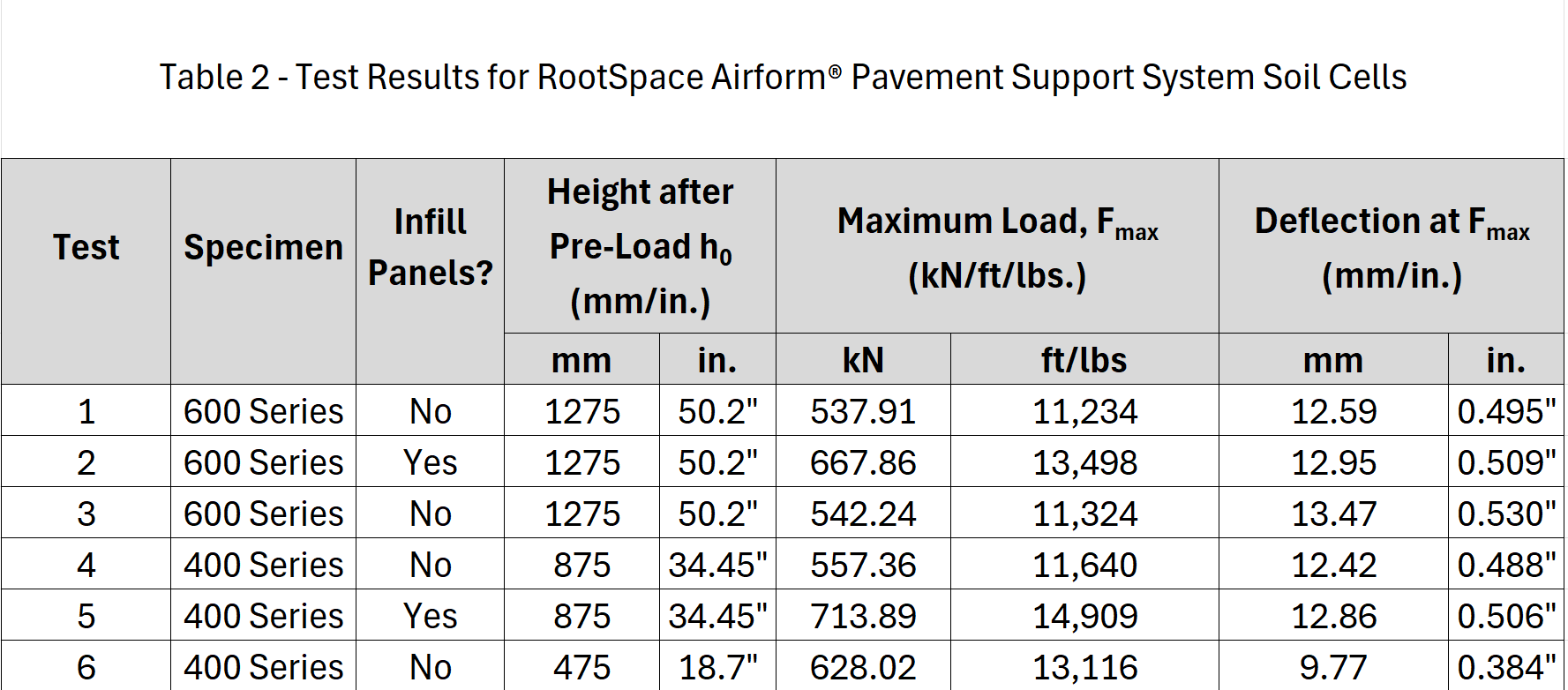

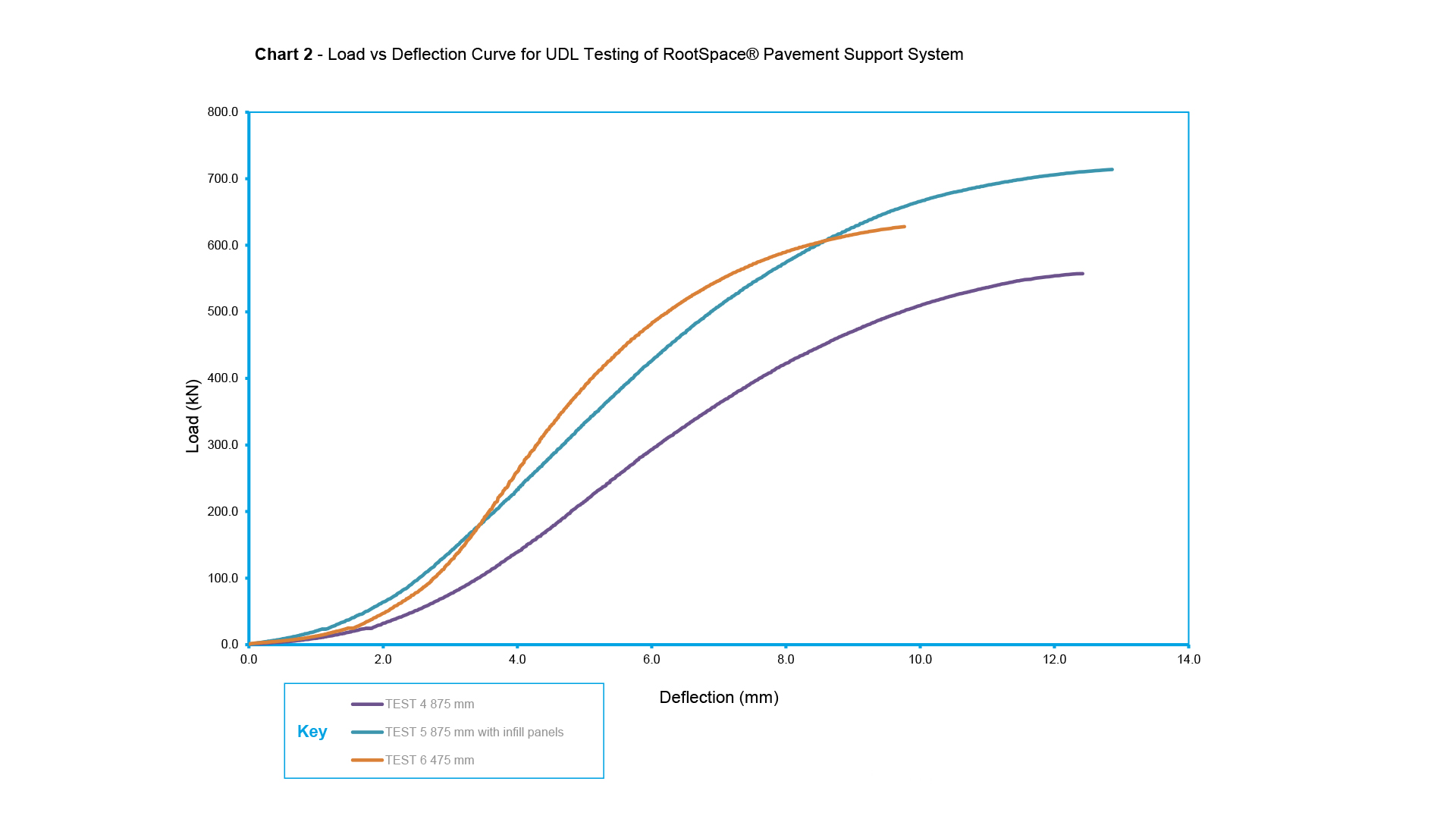

The test results, presented in Table 2 and Chart 2, provide insights into the performance of RootSpace Airform® under different configurations. Variations in maximum load (Fmax) and deflection at maximum load highlight the influence that series type and infill panels have on structural integrity and load-bearing capacity. Load-deflection and load-time curves further explain the behavior of RootSpace Airform® under compression, offering valuable data for urban infrastructure planning and design.

In addition to compression tests, Lucideon conducted tests to determine the short-term compression strength of the empty cells for underground conveyance and storage of non-potable water. The results demonstrate the robust construction and high compression strength exhibited by RootSpace Airform® across different applications.

Conclusion:

Lucideon’s comprehensive evaluation of RootSpace Airform® reaffirms its versatility and efficacy in enhancing urban infrastructure, highlighting its structural integrity and load-bearing capacity. In particular, the lateral loadbearing characteristic proved to be the strongest in class, with an assembled system highly resilient to any sideways forces.

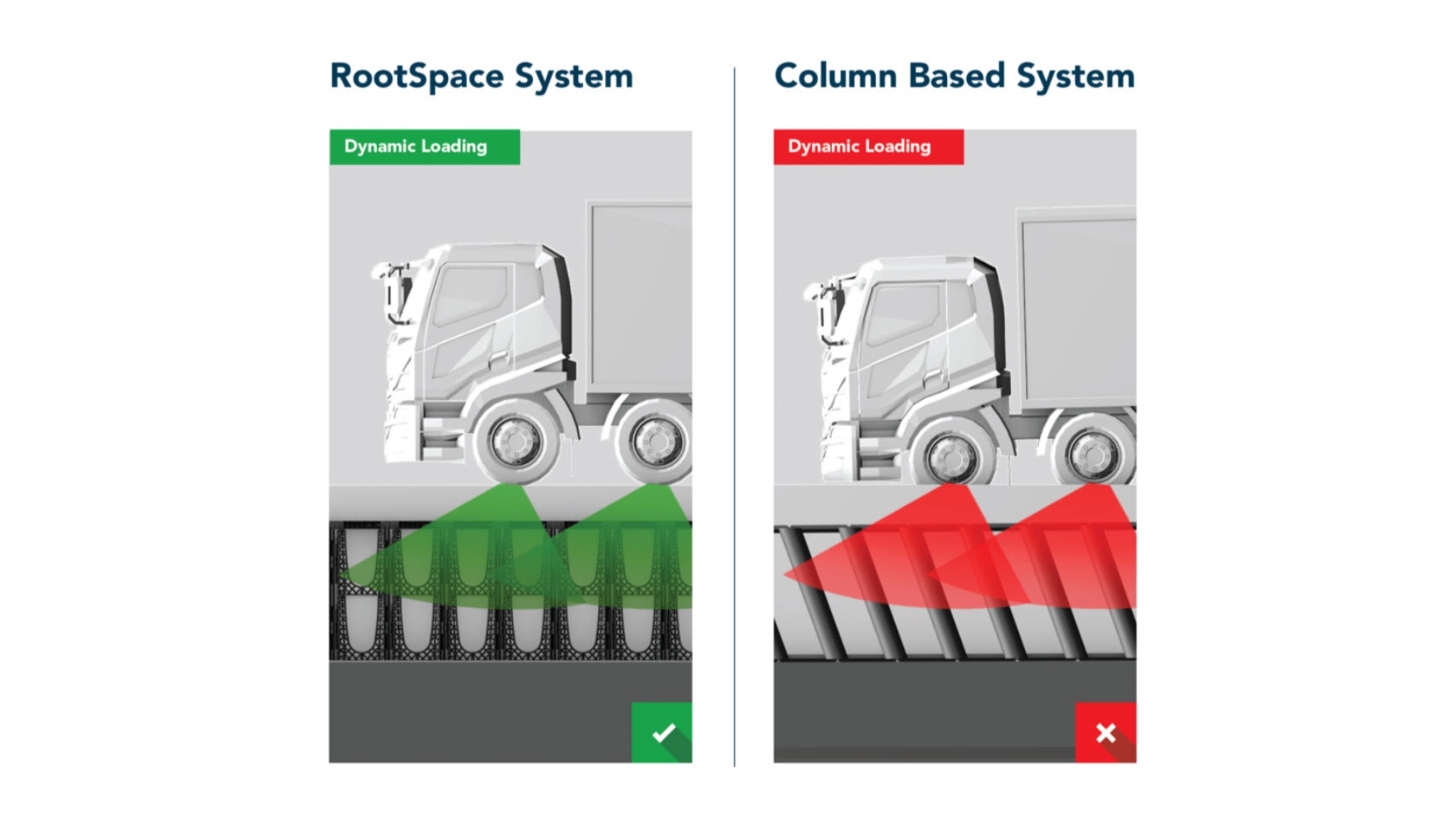

Highways engineers are particularly concerned about the ability to withstand vertical, lateral, and dynamic loading. Even if the space you’re designing is predominantly a pedestrian area, consider whether it may occasionally need to sustain vehicle traffic, for example firetruck outriggers, other emergency vehicles, or service vehicles.

RootSpace Airform® is manufactured to exceed AASHTO H-20 and Canadian Bridge Design Code vehicle load requirements when used in conjunction with vehicle rated pavement designs. This not only ensures structural integrity of surrounding infrastructure but saves labor and time when filling the cells with soil, since larger configurations can be driven on and filled by tracked construction equipment. It is of note that competitive column-based soil cell systems cannot be placed under active travel lanes, or they risk cracking under pressure and causing the pavement to sink.

The testing is underpinned by the use of North American-sourced recycled high-quality materials, which can also be recycled more than five times. With product life cycle assessments and company carbon footprint reduction, GreenBlue Urban is setting the standard against other manufacturers supplying the Canadian market.

As our towns and cities continue to evolve, innovations like RootSpace Airform® play a crucial role in building resilient, sustainable, and efficient urban environments.