The purpose of pavement is simple: to support traffic loads. Or so most would think… But what about the space below pavement? And what about the purpose pavement has as a base around urban trees? How can street trees be provided for underground with all the structural requirements of engineering a roadway? In this article, we discuss the engineering behind what maintains the structural integrity of pavement and look at how street trees can be sufficiently supported without compromising structural integrity.

Pavement Types

Paved structures provide a smooth surface for vehicles, bicycles, and pedestrians to improve efficiency and comfort. Pavement usually consists of numerous layers, placed over the in situ material, which work together to support traffic and environmental conditions. The surface layer may be made of asphalt, concrete, aggregate, or interlocking blocks. Concrete provides a rigid paved structure while most other pavements are flexible. Composite pavements are often the result of pavement rehabilitation, and exist consisting of both flexible and rigid elements.

Paving materials are also porous (permeable) or nonporous (impermeable). Permeable materials have open voids between their particles or units that allow water and air movement around the paving material. Although some permeable paving materials are indistinguishable from impermeable materials, their environmental impact is quite different.

Permeable paving materials include pervious concrete, asphalt, single sized aggregate, resin bound paving, and open-jointed blocks.

A major benefit of permeable paving is its contribution to growing healthy urban trees through the admission of vital water and air to their rooting zones. Permeable pavements behave like a natural soil surface enabling the soil moisture to fluctuate with rapid wetting followed by drying and re-aeration. Other advantages of porous paving include better management of urban stormwater runoff, resulting in less pollutants through the capture and breakdown in the subgrade, and control of erosion and siltation.

Disadvantages include the inability of permeable pavements to solely handle large rainfall events, as well as possible soil contamination, and in some instances climate limitations also arise due to road salt ineffectiveness on porous surfaces. Cost, longevity, and maintenance are also issues to consider. Most of these potential concerns, however, can be managed by integrating permeable pavements with standard stormwater facilities and prudent planning of porous locations.

Subgrade Strength

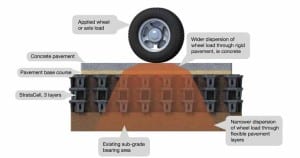

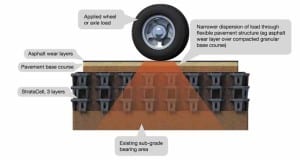

The subgrade is the soil underneath any paved structure and bears the load of any traffic on the surface. Subgrades are comprised of naturally occurring earth, disturbed existing soil, and/or fill brought from elsewhere. Even though the subgrade provides the main support of a paved surface, it is the structurally weakest component. For a pavement structure to be durable, it must protect the subgrade from deforming and does this by spreading the load over the subgrade.

The site subgrade characteristics are an important factor in pavement engineering, due to the fact that natural soils vary for any given site. Subgrade is typically composed of clay, silt, gravel, and sand, each of which has different chemical properties and particle sizes.

‘Shared space’ areas that permit pedestrian, bicycle, and vehicular traffic require rootable area underground for trees, while still maintaining a structurally sound paved surface

Wheel Loads Road Standards

The total load on a paved surface comprises the overall weight of individual loads such as vehicles and pedestrians, and the frequency of such events over time. This range of loads is conveyed in terms of a common unit of measurement, referred to as a standard reference vehicle. Any vehicle can be related to the reference vehicle by its EWL (equivalent wheel load) or ESAL (equivalent single-axle load).

The overtime deterioration of pavement is directly associated with traffic load expressed as equivalent single-axle load. When a paved structure is designed it’s predicted ESAL is accounted for and its lifetime is calculated. Once the end of its estimated lifetime arrives, the pavement is assumed to require rehabilitation in one form or another.

Direct Load

Paved areas in cities must be engineered to tolerate loads in accordance with applicable standards. Heavy emergency vehicles, such as fire trucks, must be able to access properties without causing severe pavement failure. Where underground tree pits are utilized, they must be capable of withstanding extreme loads while providing sufficient volumes of uncompacted soil for root growth.

On Main Street Markham, StrataCells were installed under the roadway and across the busy street in order to link tree pits on both sides of the road

In addition to direct vertical loads, paved surfaces are also subject to significant lateral force. Continual vehicular traffic can also cause road pavement to deteriorate adjacent to tree pit areas unless prevented. It is vital that engineered space for tree root systems are capable of supporting this kind of lateral force.

Ensuring Subgrade Strength

Interlocking structural soil cells are a strongly recommended method of ensuring paved surfaces and their subgrades receive the foundational support they require to withstand the loads placed on them. These root cells have been designed to support enormous vertical and lateral loads while providing uncompacted soil for tree roots, allowing tree root systems to be brought closer to the pavement surface.

Rigid Pavement (i.e. Concrete) Load Dispersion

Flexible Pavement (i.e. Asphalt) Load Dispersion

Structural soil cell modules lock together to form a skeletal structure with excellent vertical and lateral modular strength. StrataCells support pavement loads by dispersing pressure throughout the matrix in the same way as engineered base course.

An assembled StrataCell system has been FEA tested to 550 kPa vertical load. Engineers have even calculated that with only 300mm of granular pavement, the StrataCell matrix can support maximum vehicular traffic loads, while providing 94% void space for tree root growth or stormwater harvesting.